Improved Bond reliability through the use of Auxiliary Wires (Security Bumps and Stand-Off Stitch)

By A Mystery Man Writer

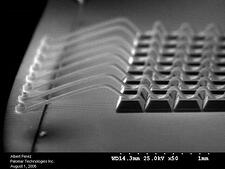

Stand-Off Stitch (SOS) has many more applications and also has many side benefits that could be incorporated into a circuit design for better wire strength properties, fewer interconnects (die to die bonding), and lower loops. Whether the need is due to poorly bondable materials, non-flat bonding surfaces, odd packaging situations, or just the need for high reliability; the integrity of a wire bond interconnect can usually be greatly improved through the proper use of Auxiliary Wires. Auxiliary Wires are defined as Security Wires, Security Bumps, or Stand-Off Stitch (aka Stitch on Bump). The old stand-by Security Wire has been an asset for several decades, however, this is being replaced by Security Bumps which require a smaller second bond termination area. Further, Stand-Off Stitch (SOS) has many more applications and also has many side benefits that could be incorporated into a circuit design for better wire strength properties, fewer interconnects (die to die bonding), and lower loops. Stand-Off Stitch bonding involves the placement of a ball bump at one end of the wire interconnect, then placing a wire with another ball at the other end of the interconnect and stitching off the wire on the previous placed ball bump. This r

Improved Bond reliability through the use of Auxiliary Wires (Security Bumps and Stand-Off Stitch)

Stitch-bond reliability evaluation by construction analysis - ScienceDirect

Void-Free Room-Temperature Silicon Wafer Direct Bonding Using

Опыт практического применения оборудования F&S Bondtec

Design and Analysis of Bonding Wire for Ka-Band QFN Package

PDF) Wire Bonding UPH and Stitch Bond Improvement using 20 Micron Diameter Insulated Wire with Security Bump

Design and Analysis of Bonding Wire for Ka-Band QFN Package

Achieving Mid-Span Wire Breaks with Security and Stand-off Stitch Bonds

Photo-Patterned Silicone Bump Bonds for Sensor Interconnects

Improve Wire Bond Capability and Reliability Through Use of Auxiliary Wires